Expertise

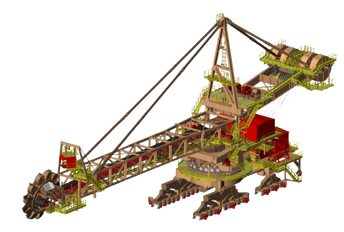

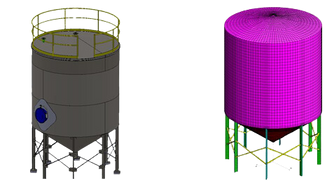

Equipment Design

Materials Handling equipment design to Australian and international standards.

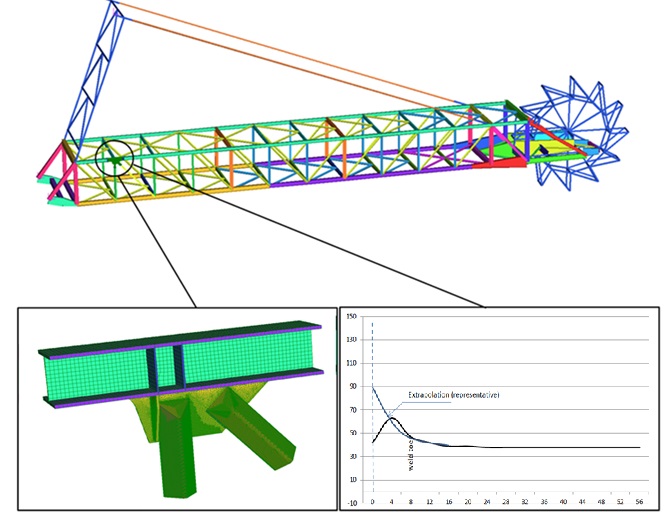

Computational Simulation

Dynamic analysis

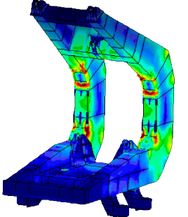

Linear and non-linear strength analysis

Thermal analysis

Critical Buckling Failure Analysis

Discreet element method analysis (DEM)

Structural optimisation

Femap NX, Ansys, Strand7, Rocky, SpaceGass

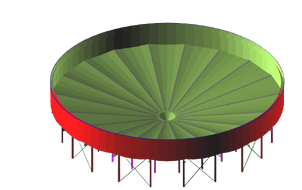

3D Modelling / Drafting

3D – Modelling

Studies and equipment layout

Detail Design

Photorealistic images and animations for construction sequences /Shutdowns methodologies / Tender presentations

Inventor; Solid Works; Advance Steel

Application of Relevant Standards

AS1418, AS1657, AS3774, AS3990, AS4024, AS4100, AS4324.1, FEM, ISO 5049, BS 7608

Design audits

Design audits help OEMs and operators ensure that equipment meets its intended performance, structural reliability, and required fatigue life.

Design compliance check

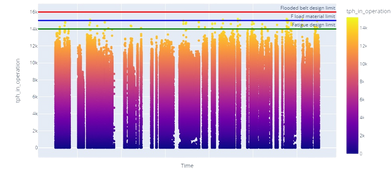

Load assumptions

stability

Fatigue life

Wheel/Foundation loads

safety against drifting

Equipment weighing validation Equipment balance review

Asset Integrity

Equipment integrity review

Site Inspections

Risk-based condition assessment, Failure Root Cause Analysis.

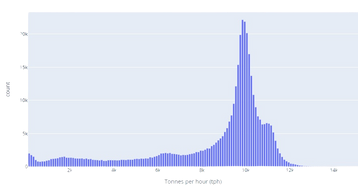

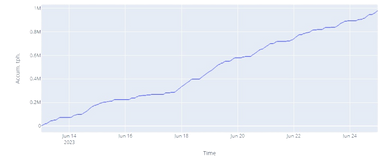

Data Analytics

Effectiveness of protection devices;

Machine operational check;

Stability verification and design parameters compliance

Maintenance

Maintenance activities in materials handling equipment often involve high-risk work. MHI supports clients with maintenance procedures and engineering, such as Temporary structure design, equipment stability control, and structural integrity during maintenance activity.

Equipment Upgrade

Capacity upgrade studies and design,

Equipment remaining life assessment

Life extension, Feasibility studies.

Structural Repairs

Failure investigation

Fatigue assessment and crack repair

Repair design.

Deconstruction

Deconstruction methodology

Design of Liftings aids

Temporary structures

Structural Integrity

Equipment stability

Sea and land transport engineering

Structural integrity and safety